The Ins and Outs of Crankshaft Engine Parts for Diesel Engines

In the vast world of diesel engines, one component stands out due to its critical role in the engine's performance and efficiency: the crankshaft engine. This essential part is often overlooked by many, yet it serves as the heart of the diesel engine, transforming linear piston motion into rotational motion necessary for powering vehicles and heavy machinery. In this comprehensive article, we will delve deep into crankshaft engines, their importance, the intricacies of their design, and how to choose the right diesel engine parts from reliable suppliers.

Understanding the Crankshaft and Its Function

The crankshaft engine is a mechanical component that converts the reciprocating motion of pistons into rotational motion. This conversion is vital for the functioning of the engine, allowing the vehicle to move. The crankshaft is typically forged from high-strength steel or iron, designed to withstand significant stress while maintaining operational integrity.

Key Functions of the Crankshaft Engine

- Power Generation: The primary role of the crankshaft is to transfer power from the pistons to the driveshaft, enabling vehicle movement.

- Balancing Engine Forces: The design of the crankshaft helps in balancing engine forces, reducing vibration and enhancing efficiency.

- Timing Coordination: The crankshaft works in conjunction with the camshaft to regulate the timing of the intake and exhaust valves.

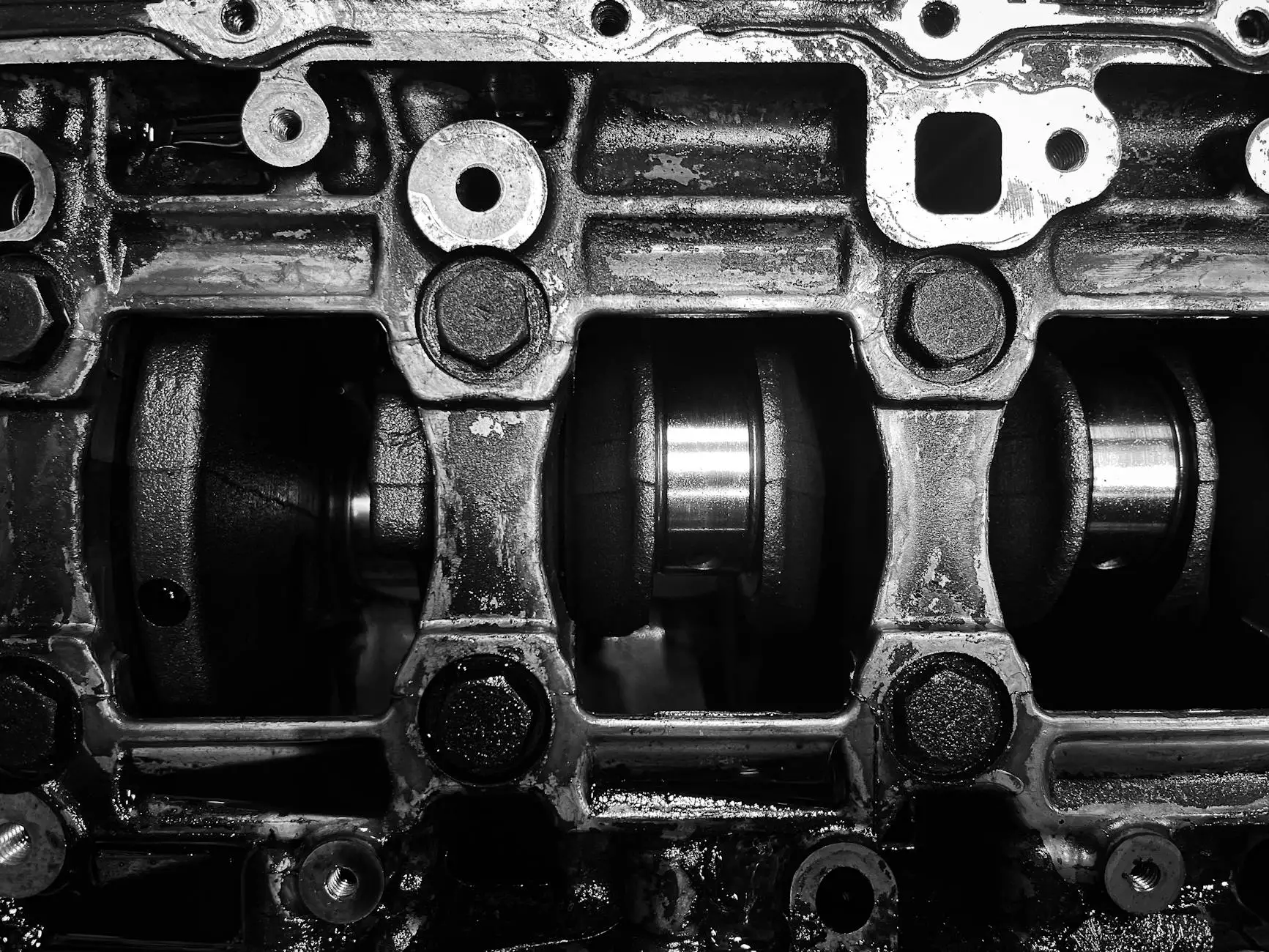

Components of a Crankshaft Engine

A crankshaft is not a standalone component. It comprises several parts that work together to ensure optimal performance. Understanding these components can aid in maintenance and troubleshooting issues. Here are the primary components of a crankshaft engine:

1. Main Journals

Main journals are the bearings on which the crankshaft rotates. These journals must be smooth and precisely machined to minimize friction and wear, essential for reliable engine operation.

2. Rod Journals

Rod journals connect the crankshaft to the connecting rods, translating the up-and-down movement of the pistons into rotary motion. The design and strength of rod journals are crucial for high-performance applications.

3. Flywheel Gear

The flywheel gear is attached to the crankshaft and helps in starting the engine. It also provides stability during engine vibrations, ensuring smoother operation.

4. Counterweights

Counterweights are added to the crankshaft to balance the rotational mass, reducing the engine's tendency to vibrate. Proper counterbalancing is key to maximizing engine life and efficiency.

Importance of Crankshaft Quality in Diesel Engines

The quality of the crankshaft engine has a direct impact on engine performance. Investing in high-quality crankshafts can prevent premature wear and failure, which can lead to costly repairs and downtime. Here are some reasons why the quality of crankshaft engine parts matters:

1. Durability and Longevity

A well-manufactured crankshaft engine can last much longer than its inferior counterparts. Using quality materials and precise engineering means that the crankshaft can handle higher stress and temperature levels without failure.

2. Enhanced Engine Efficiency

High-quality crankshaft components contribute to better combustion efficiency and overall engine performance. This leads to improved fuel economy, which is particularly important given rising fuel costs.

3. Reduced Maintenance Costs

Investing in quality parts means fewer breakdowns and repairs, ultimately leading to lower maintenance costs over the life of the engine. Quality crankshafts require less frequent replacements, saving time and money.

Selecting Reliable Spare Parts Suppliers

When it comes to sourcing crankshaft engine parts, selecting the right supplier is paramount. Not all suppliers offer the same level of quality, and choosing poor-quality parts can lead to numerous issues down the road. Here are some tips for selecting trustworthy suppliers:

1. Research Provider Reputation

Look for suppliers with a proven track record of providing high-quality diesel engine parts. Customer reviews and ratings can be very telling about their reliability.

2. Quality Assurance

Ensure that the supplier follows stringent quality control processes to guarantee that all parts meet industry standards. Certifications like ISO 9001 can be indicators of high-quality processes.

3. Warranty and Support

A reputable supplier should offer warranties on their parts, providing peace of mind regarding durability. Additionally, they should have a responsive support team that can assist with any issues or questions that arise.

Maintenance Tips for Crankshaft Engines

Ensuring the longevity and reliability of your crankshaft engine requires regular maintenance and monitoring. Here are some essential maintenance tips:

1. Regular Oil Changes

Dirty oil can lead to increased friction and wear on engine components, including the crankshaft. Regular oil changes help maintain optimal performance and protect the engine from unnecessary damage.

2. Monitoring Engine Temperature

High engine temperatures can severely impact the integrity of the crankshaft and surrounding components. Always ensure that cooling systems are functioning correctly.

3. Inspecting for Wear and Tear

Regular inspections can help identify early signs of wear on the crankshaft and other engine parts. Addressing these issues before they become significant can save considerable time and expense.

Future Trends in Crankshaft Engine Technology

The automotive industry is continually evolving, and advances in crankshaft technology are no exception. Here are some trends to keep an eye on:

1. Lightweight Materials

The move towards lightweight materials such as aluminum alloys can significantly reduce the weight of the crankshaft, improving overall engine efficiency and performance.

2. Enhanced Manufacturing Techniques

Innovative manufacturing techniques such as 3D printing are beginning to be explored for crankshaft production, allowing for more complex designs and reduced production times.

3. Integration with Smart Technologies

The integration of smart sensors into crankshaft systems can provide real-time monitoring of performance metrics, allowing for proactive maintenance and improved efficiency.

Conclusion

The crankshaft engine is an indispensable component of diesel engines, playing a crucial role in their operation and efficiency. Understanding its importance, components, and the need for high-quality parts can lead to better maintenance practices and enhanced engine performance. By choosing reliable suppliers like Client Diesel and staying informed about industry advancements, you can ensure your diesel engine remains in peak condition for years to come.

In conclusion, focusing on the quality of crankshaft engine parts and implementing effective maintenance strategies will not only prolong the lifespan of your engine but will also provide substantial cost savings in the long run. Embrace the future of diesel engine technology, and ensure your crankshaft engine stands the test of time.